Fasteners and Machining: Enhancing Durability and Performance in Production

Fasteners and Machining: Enhancing Durability and Performance in Production

Blog Article

Browsing the Globe of Fasteners and Machining: Strategies for Precision and Speed

In the complex world of fasteners and machining, the quest for precision and rate is a perpetual difficulty that requires precise focus to detail and calculated planning. From comprehending the diverse array of bolt kinds to selecting optimal materials that can stand up to extensive needs, each action in the process plays a critical role in accomplishing the preferred end result.

Understanding Fastener Types

When selecting bolts for a job, understanding the numerous types available is vital for guaranteeing ideal efficiency and reliability. Screws are used with nuts to hold materials together, while screws are flexible bolts that can be used with or without a nut, depending on the application. Washing machines are necessary for distributing the lots of the bolt and stopping damage to the material being attached.

Choosing the Right Products

Recognizing the significance of picking the appropriate products is paramount in making sure the optimal performance and dependability of the selected bolt kinds reviewed previously. When it pertains to fasteners and machining applications, the product choice plays a vital duty in identifying the total strength, toughness, deterioration resistance, and compatibility with the designated setting. Various products offer differing homes that can considerably impact the performance of the bolts.

Typical materials made use of for fasteners include steel, stainless steel, titanium, brass, and aluminum, each having its unique strengths and weak points. Steel is renowned for its high stamina and toughness, making it suitable for a large variety of applications. Selecting the right material entails taking into consideration elements such as strength requirements, ecological problems, and spending plan constraints to ensure the desired efficiency and longevity of the bolts.

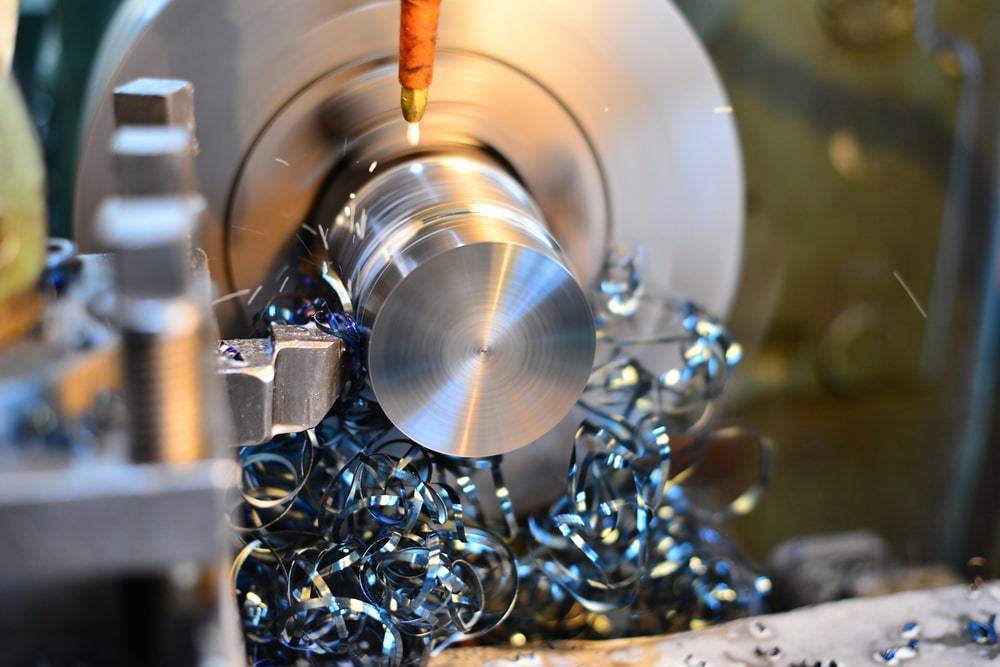

Precision Machining Techniques

In enhancement to CNC machining, other accuracy methods like grinding, turning, milling, and exploration play crucial functions in fastener production. Grinding helps accomplish great surface finishes and limited dimensional resistances, while turning is usually made use of to create round parts with specific sizes. Milling and boring procedures are necessary for forming and developing holes in fasteners, ensuring they fulfill specific specifications and function correctly.

Enhancing Speed and Efficiency

To maximize fastener manufacturing procedures, it is important to simplify procedures and execute efficient strategies that match precision machining methods. One vital method for improving speed and performance is the implementation of lean manufacturing concepts. By decreasing waste and concentrating on continual renovation, lean techniques help remove bottlenecks and optimize operations. In addition, investing in automation innovations can dramatically enhance manufacturing speed. Automated systems can deal with recurring jobs with precision and speed, permitting employees to focus on even more complicated and value-added activities. Embracing Just-In-Time (JIT) inventory management can also boost efficiency by guaranteeing that the right products are available at the ideal time, minimizing excess supply and reducing lead times. Cultivating a culture weblink of collaboration and communication amongst team members can boost total effectiveness by promoting openness, analytical, and advancement. By incorporating these approaches, suppliers can attain a balance between rate and precision, ultimately improving their one-upmanship in the bolt market.

Quality Control Actions

Executing extensive quality control measures is important in ensuring the integrity and uniformity of fastener items in the production procedure. Fasteners and Machining. Quality control procedures include different phases, beginning from the option of raw products to the final inspection of the completed bolts. This involves analyzing elements such as material toughness, structure, and longevity to guarantee that the fasteners satisfy market standards.

Regular calibration of equipment and equipment is imperative to preserve uniformity view in production and guarantee that bolts satisfy the needed resistances. Applying rigorous methods for identifying and dealing with non-conformities or flaws is vital in protecting against substandard items from going into the marketplace. By developing a thorough quality assurance structure, producers can copyright the track record of their brand name and supply fasteners that fulfill the greatest standards of performance and resilience.

Verdict

In the elaborate realm of bolts and machining, the pursuit for precision and speed is a perpetual challenge that demands careful interest to detail and critical planning. When it comes to bolts and machining applications, the product selection plays a critical function in determining the total stamina, sturdiness, corrosion resistance, and compatibility with the intended setting. Accuracy machining includes numerous sophisticated methods that make sure the tight resistances and specifications needed for bolts.In addition to CNC machining, other accuracy techniques Continue like grinding, transforming, milling, and exploration play vital roles in bolt manufacturing.To enhance bolt production procedures, it is vital to streamline operations and implement efficient methods that enhance accuracy machining techniques.

Report this page